What you need to know about

COVID-19 | Click here

What you need to know about

COVID-19 | Click here

Wednesday June 29, 2022 11:59

In this update we are going to examine Rigging: slings, chains, strops and belts and their use with overhead gantries and other lifting devices.

Rigging refers to the use of mechanical load-shifting equipment and associated gear to move, place or secure a load. Lifting loads with rigging predominantly involves working and/or load traversing at height. Risks of workers falling, or suspended loads falling must be considered.

WorkSafe NZ have provided guidance on how to be safe when load-lifting with rigging and an approved code of practice has been produced by The Ministry of Business Innovation and Employment: https://www.worksafe.govt.nz/dmsdocument/401-acop-load-lifting-rigging

This provides guidance on types of rigging, its uses and load limits for the various forms of rigging.

Overhead gantries can be found in many workshops and factories throughout New Zealand and companies will be familiar with requirements for annual certified inspections, for certificates to be on prominent display and for operatives to be properly trained in their use and maintenance.

However, to lift loads consistently and safely in a controlled manner it is not just the gantry that has to be safe to use. It is everything that is used to complete the process of lifting/moving the load from A to B. This therefore also means the slings, strops or chains that are regularly used.

Unfortunately, the rigging is regularly found to be the poor relation when it comes to suitability and effectiveness for purpose. Too often they are not stored properly, left in places where they can be easily damaged, not regularly checked for wear and tear and not correctly identified for the required load.

Examples of this neglect are unfortunately, too often seen in workplaces as the pictures below illustrate:

Such damage will create “the weakest link” and could lead to a serious accident and/or incident.

Webbing slings should be inspected for:

Webbing slings are manufactured to comply with AS 1353.1* or equivalent.

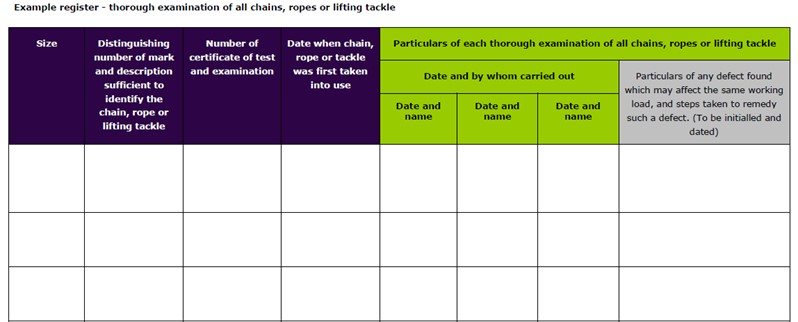

Securo recommends that all rigging used with overhead lifting devices be regularly checked and the attached inspection register template be used to record results and correction actions taken to replace worn and damaged items.

If you require further guidance, your Securo consultant is available to help, so please give them a call or alternatively, you can contact Securo head office on 0800 55 33 44.